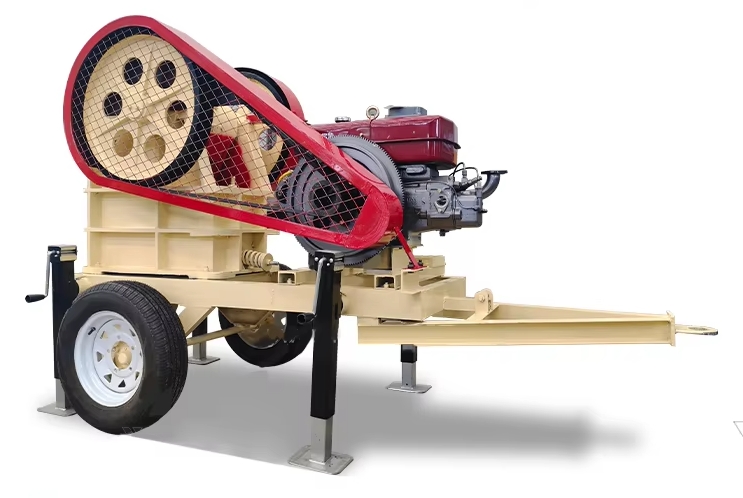

Small mobile crusher

Capacity: 1-30t/h

Applicable materials: river pebbles, granite, basalt, iron ore, limestone, quartz, diabase, construction waste, iron ore, and gold, etc

Product Description

What is a mobile jaw crusher?

A mobile jaw crusher, also known as a mobile primary crusher or mobile rock crusher, is a sophisticated rock crushing machine. It integrates a feeding system, crushing chamber, and conveying mechanism, all operating in a unified mode. This equipment can be easily relocated to optimal sites to achieve efficient crushing tasks.

Material Applications of Mobile Jaw Crushers

The mobile jaw crusher is a cutting-edge device for rock and stone crushing, offering extensive material versatility. It excels in processing a wide range of materials, such as hard rocks, granite, limestone, basalt, andesite, diabase, as well as river pebbles, various ores, tailings, and construction debris.

Performance Advantages of Mobile Jaw Crushers

(1)Versatile Functionality

The equipment offers multiple functions, capable of operating as a standalone unit or in coordination with other machinery. Its versatility allows for processing a wider range of materials, boosting production capacity by over 200%.

(2)Optimized Component Design

The optimized configuration of components enhances efficiency, featuring a reduced turning radius for improved maneuverability. This increases on-site flexibility and significantly reduces material transportation costs.

(3)Enhanced Material Processing

With superior material handling capabilities, the machine delivers higher output and crushing efficiency, meeting the stringent production demands of various processing operations.

(4)Eco-Friendly Operation

Equipped with an advanced dust suppression system, the crusher operates free from dust and noise pollution, complying with national environmental standards and promoting a greener working environment.

| Technical Parameters | |||||

|---|---|---|---|---|---|

| Model | Feed Size (mm) | Discharge Size (mm) | Capacity (t/h) | Motor Power (kW) | Dimensions (mm) |

| PE150 × 250 | 125 | 15-45 | 1.7-5.6 | 5.5 | 720×660×850 |

| PE200 × 300 | 180 | 20-50 | 3.5-13.5 | 11 | 910×750×990 |

| PE220 × 350 | 210 | 20-60 | 5-22 | 11 | 1050×950×1200 |

| PE250 × 400 | 210 | 20-60 | 5-22 | 15 | 1430×1310×1340 |

| PE300 × 500 | 290 | 20-80 | 15-40 | 18.5 | 1400×1300×1450 |

| PE350 × 750 | 340 | 40-80 | 18-60 | 22 | 1800×1921×1900 |

| PEX100 × 600 | 80 | 10-40 | 1-8 | 7.5 | 760×1100×710 |

| PEX200 × 600 | 170 | 10-40 | 5-15 | 11 | 1100×1200×960 |

| PEX150 × 750 | 120 | 10-40 | 6-20 | 15 | 1200×1530×1060 |

开启新对话